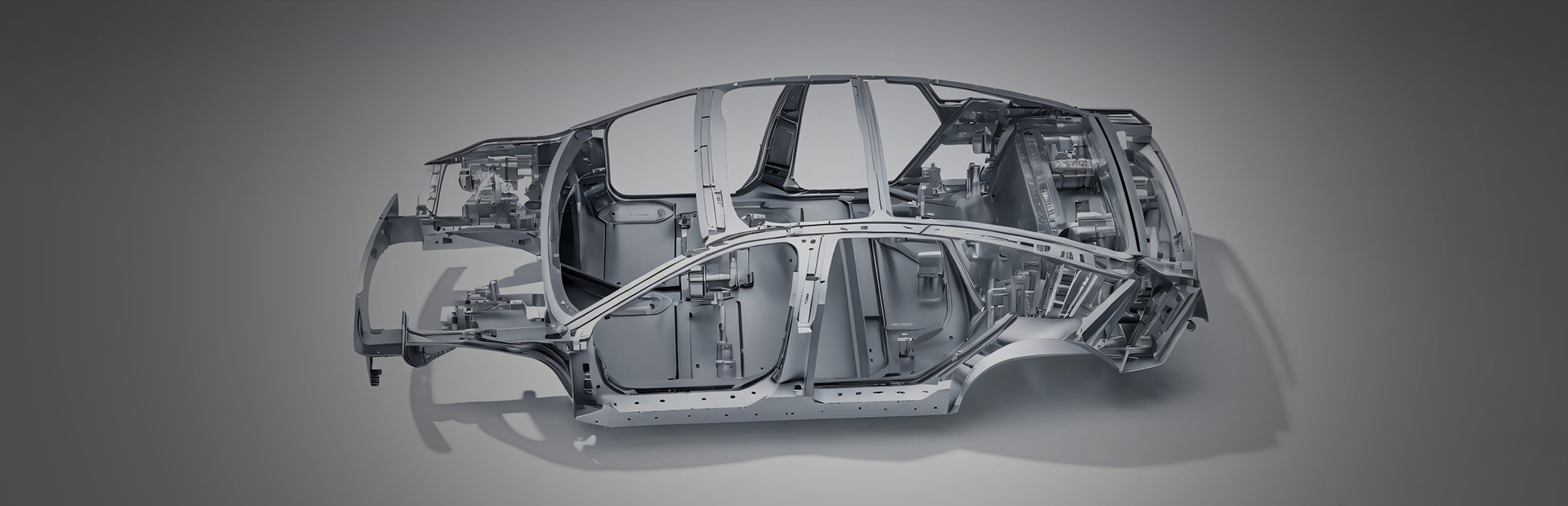

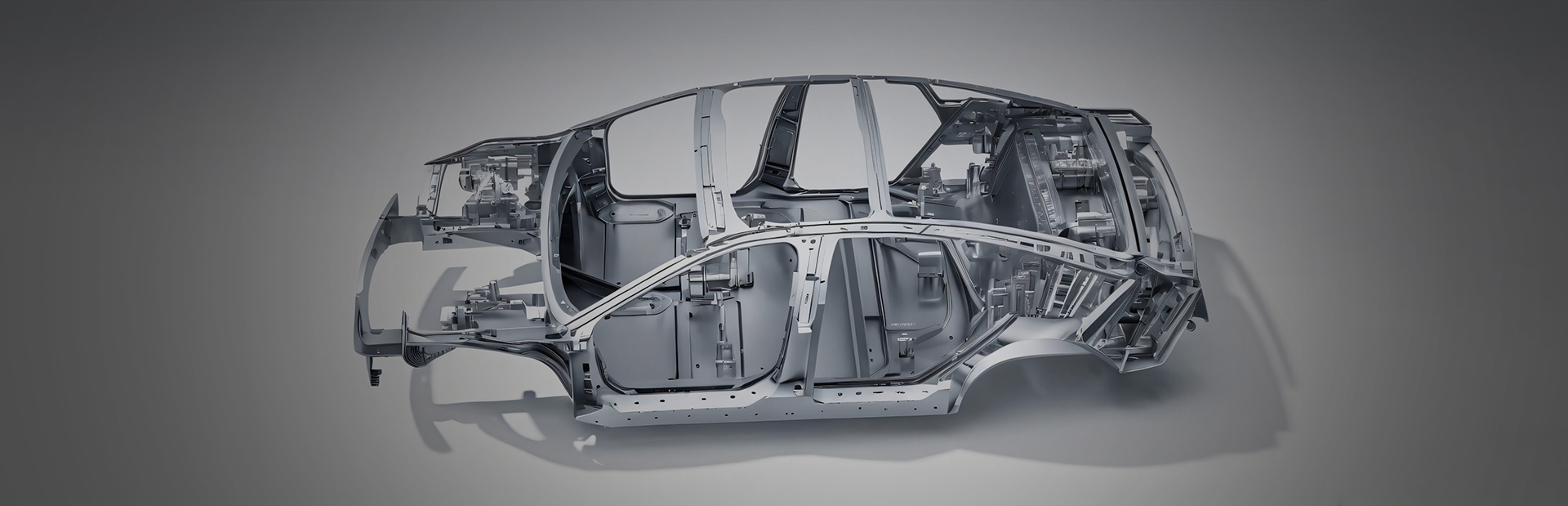

Precision casting is a high-precision metal manufacturing process that achieves exact castings through precise molding methods, enabling the production of complex and accurate parts. This technology reduces material waste, improves production efficiency, and enhances product quality. It is widely applied in aerospace, automotive, medical devices, and industrial equipment industries.